The Shift Was Almost Over

A Story of How IPTECHVIEW AI Helped Make the World Safer

The shift wasn’t dangerous.

That’s what everyone would have said if you asked them.

Forklift traffic was light. Orders were done.

Most people were already thinking about getting home.

That’s why the maintenance worker started repainting the floor lines a little early.

Nothing reckless. He had a dinner date.

And normally, at this hour, forklifts barely moved.

Ear protection on. Paint sprayer running.

Head down, focused on finishing one last section.

Two Reasonable Assumptions

At the same time, a forklift operator was returning empty pallets.

His load was stacked high. Visibility forward wasn’t great — but it didn’t need to be.

He didn’t expect anyone to be doing maintenance on the floor at this time. Because usually, no one is.

Neither of them was breaking rules in an obvious way.

They were both relying on assumptions that had been true a hundred times before.

That’s how accidents usually start.

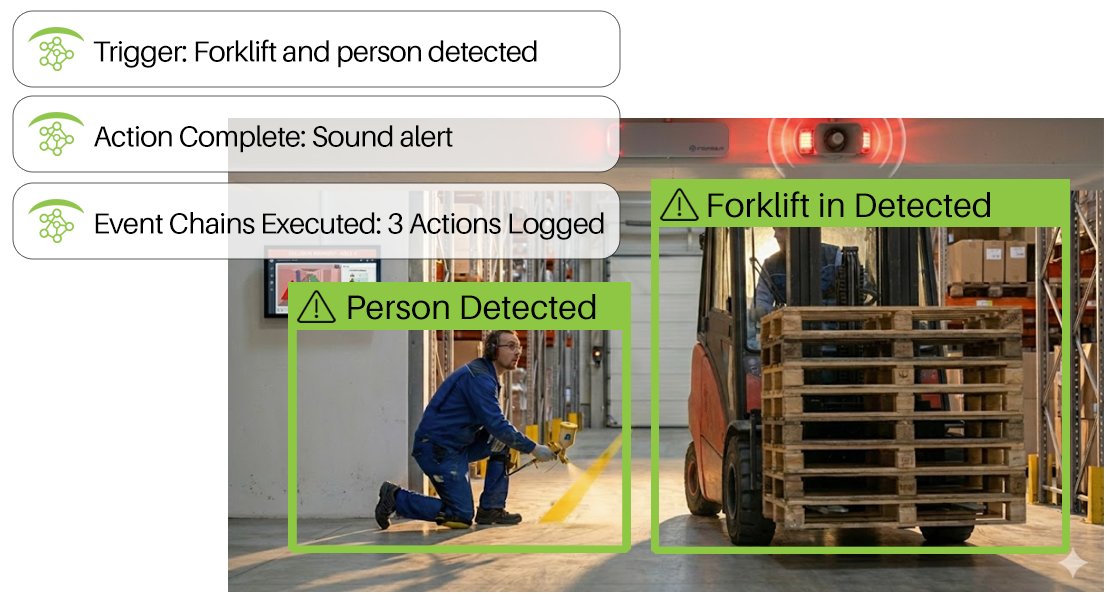

What the System Noticed

No one was watching screens.

Instead, IPTECHVIEW was doing what it was configured to do:

watch for specific high-risk combinations the tech partner and customer safety team had already agreed mattered most.

In this case:

- A moving forklift in an active aisle

- A person stationary in that same aisle

- Reduced visibility due to load height

This wasn’t about catching every risk. It was about recognizing one of the riskiest overlaps they already knew about.

The Intervention

As the forklift entered the aisle, a predefined safety routine triggered automatically.

Not an emergency alarm. Not a disciplinary alert.

Just a short, unmistakable horn tone, localized to that area.

The sound cut through the sprayer noise.

The forklift operator braked instinctively.

The painter froze, looked up, and stepped back.

Paint dripped onto the concrete. Nothing else happened.

What Happened Next Mattered Just as Much

The supervisor walked over — calm, unhurried.

No write-ups.

No accusations.

Just a simple conversation.

“Let’s make sure this doesn’t happen again.

If floor marking starts early, forklift routes need to be locked down.”

Both nodded.

Because no one felt blamed. The system hadn’t accused anyone.

It had simply made a risk visible before it turned into an incident.

Why This Didn't Create Paperwork

There was no injury. No impact. No damage. It wasn’t logged as an accident. It was logged as a prevented risk*.

And then the shift ended.

This is a story we were told that is just one example of how Video AI can help prevent potential accidents. The list of opportunities and your customers' needs for intelligent AI supervision is endless.

NOTE: The application above requires live video processing when cameras are triggered. Live video is more costly and requires more bandwidth, as well as the right cameras with fast enough processing. Discuss your projects with our sales team to make sure they are viable. Sell risk mitigation and not total risk prevention since you have no guarantee that a system will always be online. AI will give you very high positive detection rates, but it is not perfect.

Become an IPTECHPARTNER™ and help make the world safer and smarter.